The system is processing. Please wait a moment!

Vui lòng lựa chọn loại báo giá!

- Home Product MATERIALS FOR PREFABRICATED HOUSES Exterior Materials for Prefabricated Houses

Top 20+ Beautiful Wood Imitation Plastic Models - Latest Price List of Plastic Wood Today

TABLE OF CONTENTS

- What is wood imitation plastic?

- What is the structure of plastic wood?

- Characteristics of plastic wood

- Latest price list for outdoor plastic wood

- Application of plastic wood in life

- Classification of plastic wood

- Current outdoor plastic wood products

- Types of surface materials coated on PVC plastic wood

- 6 factors affecting the price of outdoor plastic wood

Plastic wood, also known as outdoor wood flooring, has become a top choice for adding beauty and sustainability to exterior spaces. In the outdoor wooden flooring supply market in Vietnam, Hoang Sa Viet Construction has maintained an important position in the choice of customers.

Hoang Sa Viet Construction's outdoor wooden flooring products are not only highly appreciated for their quality but also highly appreciated by customers for their prestige and reliability. The product's durability and aesthetics have attracted many customers to choose this material for their exterior spaces.

With a commitment to quality assurance and dedicated service, Hoang Sa Viet Construction constantly strives to bring the best quality products and perfect services to customers. This has helped their outdoor wooden flooring products become the top choice for many construction and exterior space decoration projects.

What is wood imitation plastic?

Plastic wood, also known as wood plastic composite, or abbreviated as WPC (Wood Plastic Composite) in English, is a new material synthesized from wood pulp, plastic, and some additives. cellulose-based or inorganic. Made from natural materials such as sawdust, shavings, or from raw material plantations, plastic wood is completely environmentally friendly.

During the production process, materials such as HDPE, PVC, PP, ABS,... are used to combine with wood pulp and other additives. These ingredients are then mixed and passed through production lines to create compound granules. Next, this compound granule will be fed into extruders and presses to form final product shapes according to specific requirements.

This production process not only helps create quality products but also ensures uniformity and stability of plastic wood products. At the same time, the combination of natural ingredients and plastic also gives the product flexibility, durability, and ease of processing and use.

What is the structure of plastic wood?

Composite wood-plastic products are formed from two main components: wood and plastic, with wood extracted from a variety of sources such as sawdust, pulp fibers, peanut shells, bamboo, rice husks,... In Meanwhile, the plastic can be PVC, PP, ABS, HDPE, or other types of plastic.

The production process begins by thoroughly mixing plastic powder with wood components to create a homogeneous mixture. This mixture will then be passed through extruders or presses to create final product shapes according to specific requirements.

To improve the quality and properties of the product, additives such as jointing agents, stabilizers, reinforcing agents, and flotation agents are often added. These substances help improve the adhesion, color, and durability of the product.

Composite wood-plastic products usually include four main parts:

- Base PVC sheet: is the basic part of the product, creating the foundation for other surface layers.

- Adhesive layer: helps tightly bond between the surface panel and the material panel, and is also waterproof.

- Patterned printed PVC plastic film: is the top layer, resistant to light scratches and difficult to fade.

- Surface protection film: creates shine and luxury for the product, while protecting the surface from external impacts.

Characteristics of plastic wood

Compared to the long development history of natural wood, plastic wood is a new material. However, with the scarcity of natural wood in the modern era, plastic wood has become an effective alternative, bringing the following notable advantages:

Flexible shaping ability : Plastic wood can be formed into any shape according to specific requirements, suitable for many different use cases.

Aesthetic surface : Plastic wood has a surface similar to natural wood, creating a natural and highly aesthetic feeling.

Outstanding properties : Plastic wood has many unique properties such as moisture resistance, rot resistance, sturdy and durable.

Termite and corrosion resistance: Plastic wood is not affected by termites and corrosion, helping to increase longevity and long-term use.

Environmentally friendly and requires little maintenance : Plastic wood does not harm the environment and does not require much cost for maintenance and repair.

No need to paint: Plastic wooden bars do not need to be painted because during the production process, the necessary colors are mixed with UV protection, helping to protect the surface and color of the product.

SEE MORE PRODUCTS:

High strength resistance : Plastic wood has good bearing capacity, helping projects to be built firmly and durable over time.

Light weight : With a lighter weight than natural wood, plastic wood reduces the weight of projects, helping to limit load and increase mobility.

Easy to engrave and print : The surface of plastic wood can easily be engraved and printed with motifs or messages, creating highlights and personalization for products.

Easy to shape : Plastic wood has the ability to shape flexibly, even complex details that are difficult to make with natural wood.

Environmentally friendly : Plastic wood is made from recycled materials and is not harmful to the environment, reflecting the industry's commitment to environmental protection.

Reasonable price : Compared to natural wood, plastic wood has a significantly lower price and saves construction and installation time while still ensuring quality for construction projects.

Latest price list for outdoor plastic wood

Note that this is only a reference price list and specific prices may change depending on the specific requirements of each project. To receive detailed advice and quotes, please contact us. We are committed to bringing satisfaction and the best quality to customers.

| CATEGORY: OUTDOOR PLASTIC WOOD FLOOR | ||

| Product's name | Illustration | Reference price |

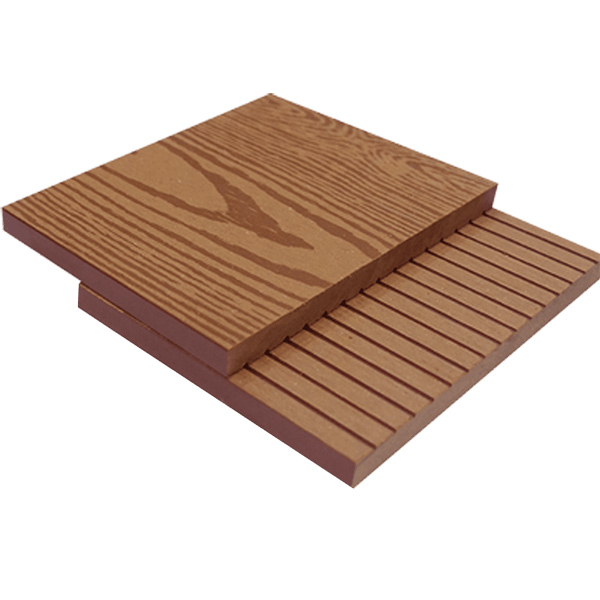

| Plastic wood flooring (no coating) |

|

975,000 – 1,020,000 VND/m 2 |

| Plastic wood flooring (polymer coating) |

|

~1,250,000 VND/m 2 |

| CATEGORY: Blister-shaped outdoor plastic wood | ||

| Outdoor plastic wood blister |

|

805,000 – 860,000 VND/m 2 |

| CATEGORY: WOOD PLASTIC WALL PANELS | ||

| First generation plastic wood panel (no coating) |

|

860,000 – 920,000 VND/m 2 |

| First generation plastic wood panel (polymer coated) |

|

~1,025,000 VND/m2 |

| PVC wood panel coated with ASA |

|

~886,000 VND/m2 |

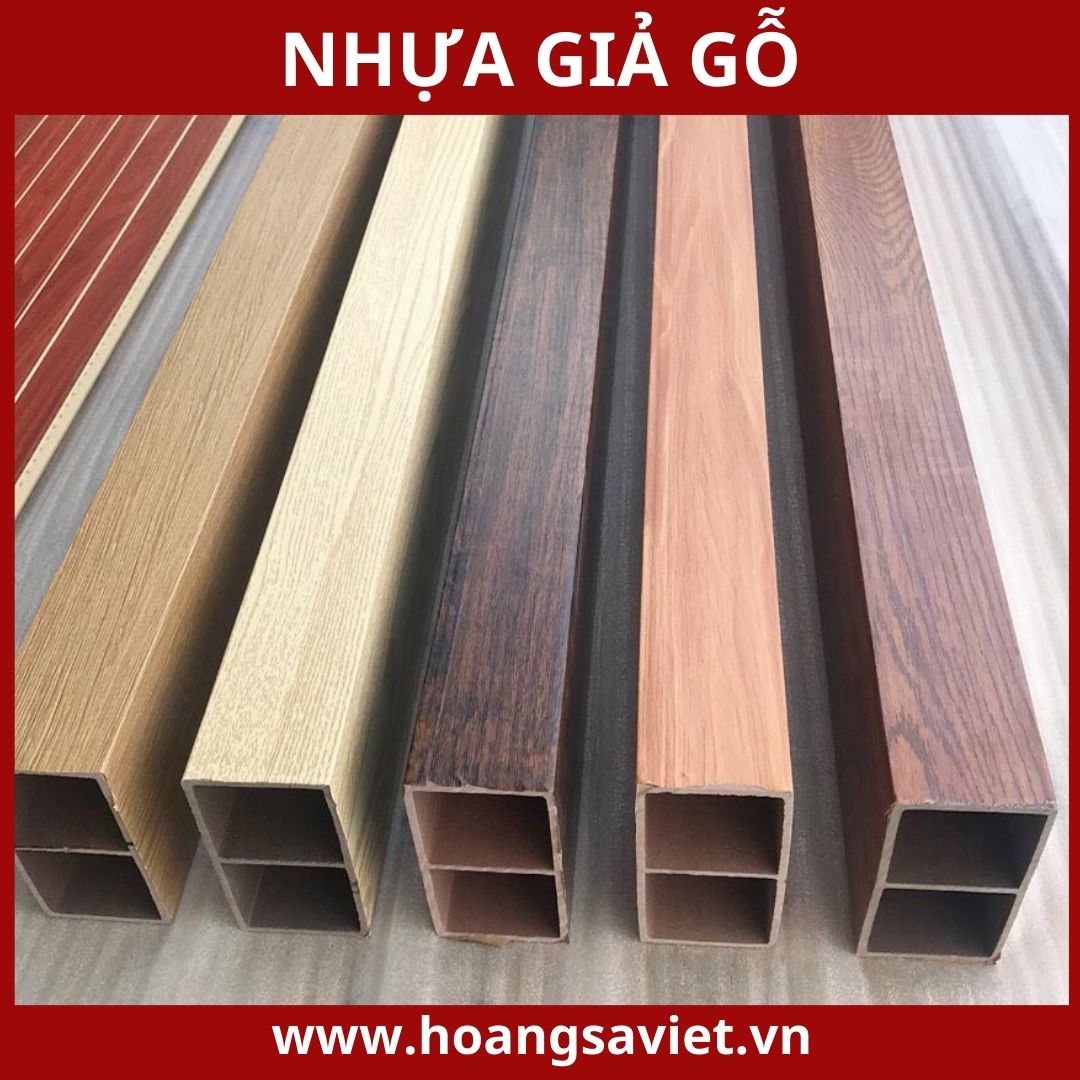

| CATEGORY: PLASTIC WOODEN BAR | ||

| Plastic wooden bars |

|

70,000 – 330,000 VND/meter long |

| CATEGORY: WOOD AND PLASTIC PILLARS | ||

| Plastic wooden pillars |

|

330,000 – 510,000 VND/meter long |

SEE MORE PRODUCTS:

Application of plastic wood in life

PVC plastic wood products are suitable for both interior and exterior projects, but they are often strongly used in exterior projects such as making flooring, railings, fences, park benches, door frames and many other applications.

Plastic wood for indoor furniture

Plastic wood has become a popular choice for home interiors, no longer unfamiliar to many families. This popularity is not only because of the outstanding advantages it brings but also because of the convenience and aesthetics that plastic wood brings.

For many families, plastic wood is not only a decorative material, but also a much more economical solution than using natural wood. Although the price is lower, plastic wood still retains its natural beauty, no less luxurious and quality.

The applications of plastic wood in interiors are very diverse, from ceiling cladding, wall cladding, stair railings to other decorative details. With the ability to closely simulate natural wood, plastic wood not only makes the interior space beautiful but also adds luxury and class.

Besides, plastic wood also brings convenience in installation and maintenance. Not only is it easy to transport and install, but it also requires little future maintenance costs. This helps families save both time and money when using plastic wood for their furniture.

Outdoor plastic wood flooring

Plastic wood panels are becoming a popular choice for many exterior projects today. Specifically, they are widely used in projects such as swimming pools, gardens, balconies, walkways, outdoor wooden plastic gates, and many other projects.

A typical example is the use of plastic wood panels for areas around the swimming pool. This product not only has aesthetic beauty but also has good resistance to environmental factors such as water, sunlight, or humidity. Thanks to this feature, plastic wood planks help the swimming pool become luxurious and durable, while also minimizing future maintenance and repairs.

In addition, plastic wood planks are also used to create floors for gardens, balconies, and other exterior walkways. With rot resistance, moisture resistance and high durability, this product brings not only beauty but also comfort and convenience to users. At the same time, using outdoor plastic wood panels also helps prolong the life and create lasting beauty for construction projects.

Plastic wooden slats

Plastic wooden slats are becoming an indispensable part of many construction projects, from houses to luxury villas. They are widely used to create flower trellises, sunshades or balcony decorations. For each position in the project, this product performs its role excellently, contributing to enhancing the beauty and aesthetics of the living space.

Plastic wooden slats not only bring aesthetic beauty but also have good resistance to harsh environmental conditions. With their characteristics of not rotting and not being affected by the effects of water and sunlight, they help preserve the freshness and beauty of green spaces all year round without having to worry about maintenance or periodic repair.

At the same time, flexibility in design and color choice also helps plastic wooden louver trusses suit all architectural styles and decorative ideas. Thanks to these advantages, they become an indispensable part, contributing to creating luxury and comfort for each family's living space.

Classification of plastic wood

Currently, there are two popular types of plastic wood used: PE-based plastic wood and PVC-based plastic wood. Each of these types has its own characteristics, suitable for different uses. PE-based plastic wood is often preferred for outdoor projects, while PVC-based plastic wood is often the top choice for indoor interiors. This helps optimize the application of each type of plastic wood for different types of projects, ensuring the performance and durability of the product.

Outdoor plastic wood

Outdoor plastic wood is often produced from PE (Polyethylene) raw materials, combined with wood pulp and other additives. Through modern production processes, these components are combined to create plastic wood bars with many different shapes and designs such as large stripes, small stripes, wood grain, or roughness.

This type of material is designed to replace traditional materials such as brick, stone or wood, to overcome their disadvantages. For example, bricks are often slippery, wood is expensive, and stone is difficult to work with. Outdoor plastic wood was born with outstanding advantages, becoming a popular choice for outdoor projects such as swimming pool floors, sunshades, house exterior wall cladding, garden floors, and many other applications. .

Wood plastic composite indoors

Wood plastic composite is often used indoors with PVC-based materials, combining PVC plastic with wood powder and additives to increase adhesion. The distinction between these two types of plastic wood indoors and outdoors mainly comes from the origin of the material, with PVC being thinner and lighter and lower in price than PE. At the same time, different production processes also create differences in the characteristics of the two types of products, giving rise to price differences.

Indoor plastic composite wood models are often more water and heat resistant than outdoor plastic wood models, but are not designed to withstand harsh weather environments like outdoors. Therefore, they are not usually used for outdoor projects. However, outdoor composite wood-plastic materials can still be used for interior purposes as decorative louvers or as indoor wall and floor materials if desired.

Current outdoor plastic wood products

Wood plastic composite flooring

There are three popular types of outdoor composite wood plastic flooring used for many different purposes such as garden floors, balconies, swimming pools, outdoor cafes, park paths, cruise ports and many other projects. other:

Rectangular hole hollow floorboard size 140x25 : Usually applied to family swimming pool floors, walkways around family aquariums, miniature landscape decorations and locations with little impact and low traffic density. .

Round hole hollow floorboard size 150x25 : Suitable for large-scale projects such as roads in parks, public swimming pools, resorts and projects with strong aesthetic and load-bearing requirements.

Solid flooring size 150x25: Used in public buildings such as seats, large floors, public roads and locations with high traffic density and can withstand strong impacts.

SEE MORE PRODUCTS:

Plastic wooden poles

Plastic wooden columns are often applied in structures such as fences, decorative columns and railings. There are three common types of plastic wood columns as follows:

Square plastic wooden columns : Have diverse sizes such as 120x120mm and 100x100mm. Often used for projects that require sturdiness and aesthetics, such as decorative columns or load-bearing columns in fences.

Rectangular plastic wooden columns: Common size is 50x100mm. Suitable for projects that require simplicity and economy, such as making columns in fences or railings.

Outdoor plastic wooden bar

Flat outdoor composite plastic wooden bars are often widely used in many different applications such as making flower trellises, sunshades, decorating apartment balconies, or even in other outdoor hut projects.

This is a versatile and flexible material that helps create beautiful and sustainable exterior spaces. Outdoor composite plastic wood slats are often designed to withstand the effects of harsh weather while still retaining their long-lasting shape and color.

Outdoor plastic wood blister

Multi-purpose outdoor plastic wood panels are an intelligent solution to optimize apartment balcony space. By using this product, not only does it create a living environment close to nature, but it also opens up a more frugal and sophisticated lobby space for the family.

With quality plastic wood material, this multi-purpose blister is not only able to withstand all weather conditions but also ensures aesthetics and comfort for residents. This helps create a cozy and enjoyable living environment, stimulating the creativity and relaxation of everyone in the family.

Plastic wood panels for outdoor walls

Outdoor plastic wood wall panels are an excellent choice to create a highlight for the project, bringing a warm and close space to nature. With the ability to replace stone, brick and concrete, this product not only beautifies but also helps save costs and effort during the construction process.

Made from high-quality plastic wood materials, outdoor wall panels are not only rot-proof and moisture-resistant but also anti-corrosion and durable in harsh weather, ensuring durability and beauty for the project. progress over time.

Types of surface materials coated on PVC plastic wood

Acrylic-coated PVC plastic wood

PVC plastic wood coated with acrylic is an effective solution in increasing aesthetics and product protection. Acrylic coating helps create a smooth and durable surface that resists scratches and fading. At the same time, it also helps protect the PVC wood layer under the coating from the effects of the external environment such as water, sunlight, chemicals, and abrasion. This makes the product have a long lifespan and is easy to maintain, keeping the surface always fresh and durable over time.

Laminate-coated PVC plastic wood

Laminate-coated PVC plastic wood is a smart combination of plastic wood material and laminate layer, creating a product with many notable advantages. The laminate layer protects the surface of PVC plastic wood from external influences such as scratches, impacts, and abrasion. It also provides a smooth glossy finish, giving the product a luxurious and aesthetic feel.

In addition, the laminate layer also increases the waterproofness of the product, protecting PVC wood from moisture and rot. This makes PVC laminate an ideal choice for applications in wet environments such as bathrooms, kitchens, or outdoor floors. The combination of PVC wood and laminate provides high performance and long-term durability, while creating a beautiful and modern look for the space used.

Veneer coated PVC wood

Veneer-coated PVC wood is a structural material combining PVC wood and veneer, bringing unique and diverse advantages for decorative and interior applications.

Veneer is produced from thin layers of natural wood, often cut from panels with high aesthetic properties such as oak, plywood, or ash. This veneer is then glued or coated onto the surface of the PVC wood to create the final product.

The combination of PVC wood and veneer layer brings remarkable advantages. Veneer brings out the natural beauty and warmth of natural wood, while PVC laminate provides durability and water resistance. This combination not only creates a product with a beautiful appearance but also has good bearing capacity and is easy to preserve.

Veneer-coated PVC wood products are often used in interiors, such as making wooden doors, wardrobes, tables and chairs, or decorative items. The diversity in wood types and veneer patterns also allows creating unique and rich designs for used spaces.

Painted PVC plastic wood

Painted PVC wood is a material created by applying a layer of paint to the surface of PVC wood. This manufacturing process involves applying high-quality lacquer to the surface of PVC plastic wood through coating or surface treatment methods.

The matte paint layer gives PVC plastic wood products a luxurious beauty and variety of colors. Flat paint can be applied in a variety of colors and patterns, from simple colors such as white, black, gray to more striking and complex colors such as red, blue, yellow.

The combination of PVC wood and matte paint brings special advantages. PVC laminate provides durability and stability, while the matte finish creates a smooth and glossy finish to the surface. In addition, the lacquer layer also helps protect the surface of PVC wood from external influences such as sunlight, water, and chemicals.

Painted PVC wood products are often used in interior and exterior decoration, such as making wooden doors, kitchen cabinets, tables and chairs, or decorative items. This product's high durability and water resistance make it a popular choice for indoor and outdoor spaces.

SEE MORE PRODUCTS:

Wood PVC Film Face Chipboard

PVC Film Face Chipboard is a material created by combining chipboard (pressed wood chipboard) and a layer of PVC film coated on the surface. The manufacturing process involves joining chipboard panels into large panels then applying PVC film using high pressure and temperature.

PVC film is applied to the surface of the chipboard to provide beauty, aesthetics and durability. This film layer can be designed with many different colors, patterns and materials, creating diversity and richness for interior and exterior decoration applications.

6 factors affecting the price of outdoor plastic wood

Plastic wood brand

In today's plastic wood market, the role of brand is very important and has a significant influence on both price and product quality. Famous and reputable brands are often valued more highly by consumers because they have built up their reputation over time. Therefore, products from these brands often have higher prices than other brands. However, this also means that consumers can trust the quality of products and after-sales services from reputable brands.

Sales agent

When receiving a quote for plastic wood products, you will also be informed about shipping and installation costs. This means that the final price of plastic wood will depend on many factors, including transportation distance, convenience of installation, and other factors such as specific geographical conditions.

Materials

Plastic wood is mainly made up of two main ingredients: wood pulp and plastic powder, along with some other additives. The price of the product is often determined based on this main material.

Among plastics, HDPE plastic is often able to withstand harsh outdoor environmental conditions better than PVC plastic. For outdoor applications, plastic wood products are often made from PVC and are often coated with ASA on the surface to increase color fastness and weather resistance.

SEE MORE PRODUCTS:

Product dimensions

The size of outdoor plastic wood products also plays an important role in determining the price. Products with large sizes and high thickness often cost more than products with smaller sizes. This is because the material usage and manufacturing process for larger and thicker products can require greater cost and effort.

Quantity supplied

When you buy plastic wood in large quantities, there will often be a more favorable price than buying in small quantities. This is because suppliers often have discount policies for large orders, to encourage bulk purchases from customers.

Production technology

To ensure product quality, today's manufacturers must make significant investments in production equipment. This investment cost not only includes the purchase of advanced machinery and equipment but also includes maintaining and upgrading them over time. All of these factors affect the price of plastic wood products.

Hiện chưa có đánh giá nào về sản phẩm này!

.jpg)

.jpg)

.jpg)