The system is processing. Please wait a moment!

Vui lòng lựa chọn loại báo giá!

- Home Product prefab modular house

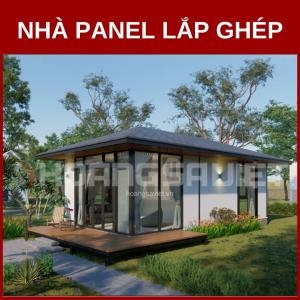

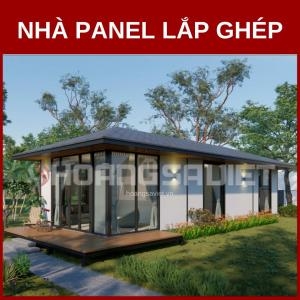

House Panel Assembly

Code: NPLG

- Unit price: From 4.5-5.5 million/m2

- Model: Prefab Panel House (NPLG)

- Made in Viet Nam

- Brand: Hoang Sa Viet Construction

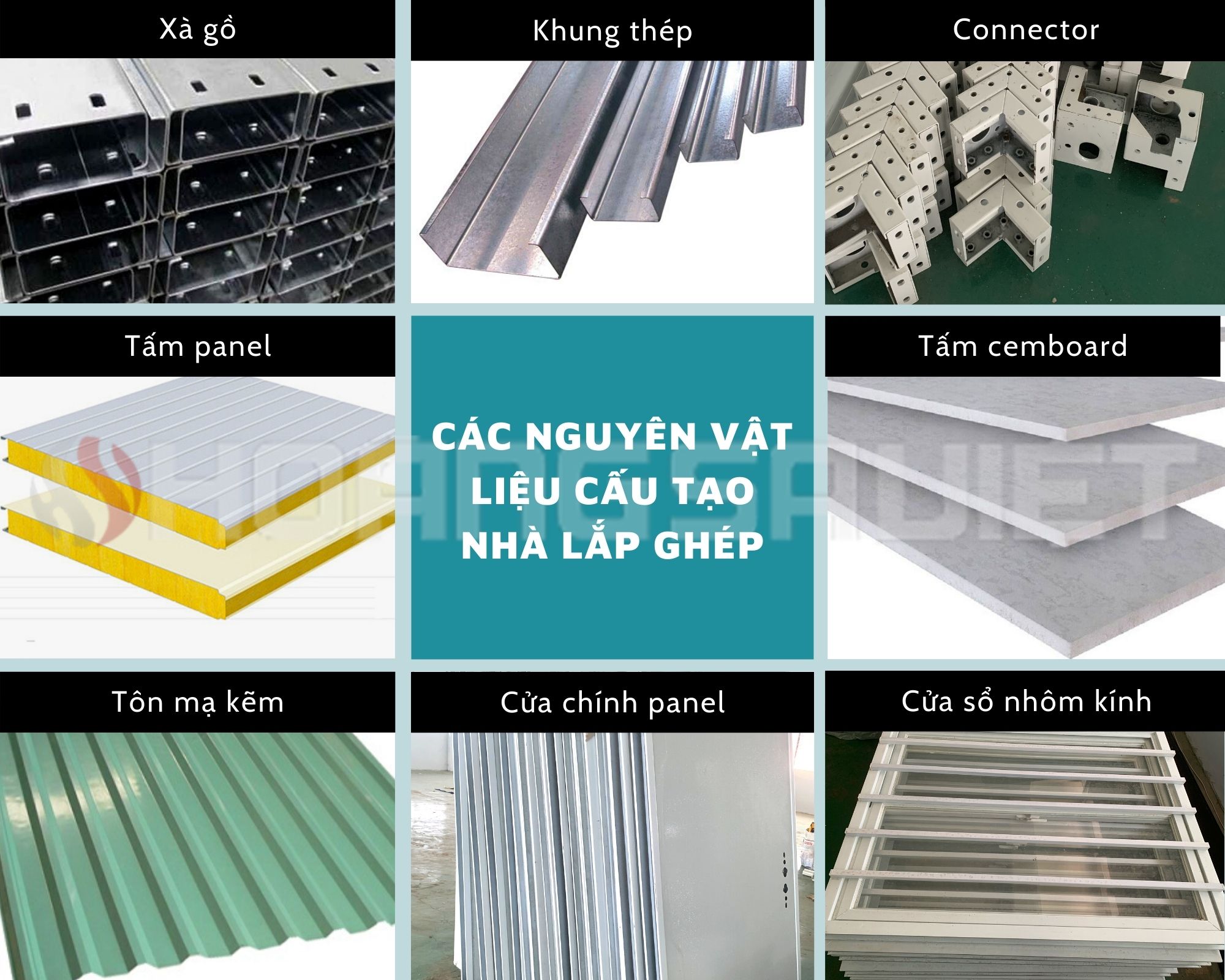

- Frame material: 2.5mm thick U160mm steel - tempered - electrostatic

- Wall material: High quality Glasswool Panel, 3 layers thick 50mm

- Heat insulation: 95%

- Fire resistance: 100%

- Connection type: Smart Connector

- Electrical system: Basic (LED light, socket, CB)

- Warranty: 20 Years

What is prefab panel house?

Pre-assembled panel house - as the name suggests, this composite house is composed of lightweight materials, the wall panels are mainly selected by Hoang Sa Viet as high-quality Panel Glasswool as the material to be assembled together. with Cemboard cement board as floor lining, strong U-shaped stamping frame - electrostatic,... Each construction project will correspond to a different type of prefabricated house based on its own technical method at home. Specialized production machines, bringing solidity combined with beautiful colors, high aesthetics for the house.

Why choose panels for the installation of prefab houses?

Insulation panel is a building material that is composed of two outer sides of corrugated iron, the core is made of synthetic glass wool fiber, has the features of heat insulation, sound insulation, high electrical insulation, non-combustible, soft and durable. Good elasticity, ideal durability

Panels not only help overcome the limitations of traditional materials. It also offers many competitive advantages compared to other materials on the market. Some reasons why Hoang Sa Viet Construction chooses glass wool panels as walls for prefab houses are:

-

Effective explosion-proof: With good fire-resistant components, fiberglass insulation panels can prevent the growth of fire, fight fire very effectively, and do not produce other harmful gases. .

-

High insulation resistance: With a special design, there are tiny air layers between the microfiber glass wool, so the insulation performance of the fiberglass panel is very good, even with the weather 39 - 40 degrees or so. This is the outstanding advantage of insulated wall panels that are favored by investors.

-

Good sound insulation: Because it is composed of 3 layers, the glasswool panel has very good noise reduction ability. Solve the current alarming noise pollution situation.

-

Quick construction: The material to create the insulation panels is quite light. Simple and easy installation, shortening construction time, quickly checking and accepting works, labor force.

-

Cost saving: Thanks to its affordable price, easy cleaning, reducing labor resources, it saves a lot of costs for investors. Besides, the insulation panel with many diverse designs, modern and luxurious design ensures high aesthetics.

-

High durability: With 2 outer layers of corrugated iron, the fiberglass core is soft but very elastic. Therefore, this product has the ability to recover, withstand shocks, shake or be suppressed. During use can increase the solidity and stability of the works.

The process of building a prefab panel house

-

Laying the foundation: For areas with soft ground, choose a foundation with light load and will not settle after a long time.

-

Manufacturing, calculating and finishing the components of the prefab house at the factory

-

Frame erection: Workers will begin to erect the main frames of the house with steel frames and use bolts to hold and shape the structure of the house.

-

Installation of wall and wall systems with mineral wool panels and galvanized corrugated iron roofs for assemblers

-

Install the main door panel system, aluminum and glass windows

-

Paving a layer of lightweight concrete Cemboard, then performing other types of flooring on the floor for the prefab house

-

Install ventilation, heat protection, lightning protection, electricity and water systems and sanitary equipment…

-

Acceptance of prefabricated houses. Check carefully whether the roof is leaking or not, the walls and walls are airtight, the floor is drained, and the sound and heat insulation of the house is good in rainy and sunny times.

.jpg)

The applicability of prefab houses with panels in life

Due to the function of the prefab house, it is easy to use, move, does not take much time and cost, is modernly designed, light in weight but still ensures rigidity, safety, and quick installation. Versatile, so it is often used in places such as:

-

Corporate office

.jpg)

-

Worker housing

-

Clinics

-

Family vacation home in the countryside

-

Single-storey house with bedroom and bathroom

.jpg)

content

content