The system is processing. Please wait a moment!

Vui lòng lựa chọn loại báo giá!

- Home Product MATERIALS FOR PREFABRICATED HOUSES Prefabricated Flooring Materials

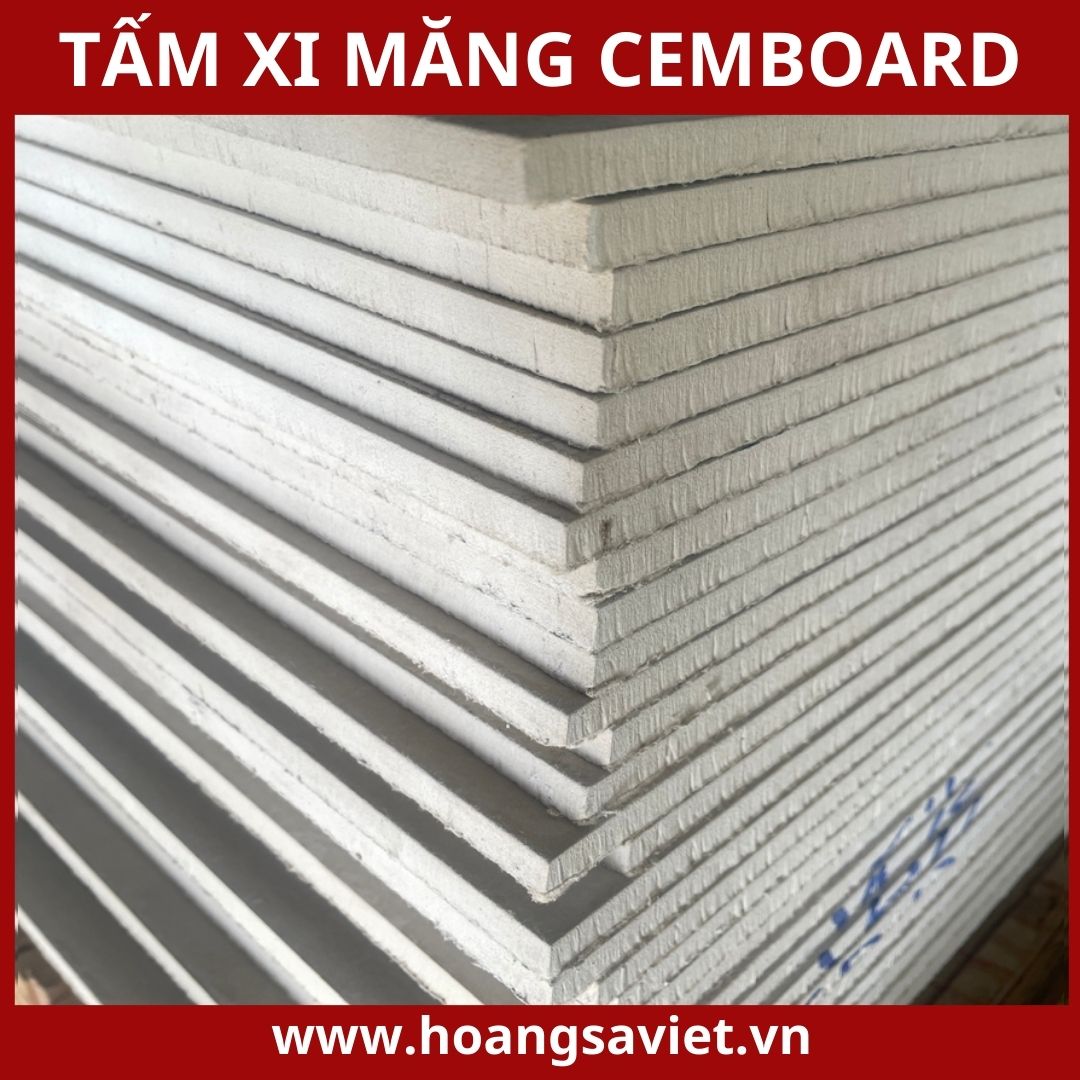

Cemboard Cement Board

TABLE OF CONTENTS

In recent years, the trend of using lightweight materials in construction has become increasingly popular. One of the most popular materials is Cemboard. This product has received many positive reviews thanks to its high durability, ease of construction, and affordable price. However, users often have many questions about the features and applications of Cemboard panels such as: is Cemboard cement panels waterproof, what is the bearing capacity, can it be painted and cut, and what is the price? and where to buy to ensure reputation and quality while still having a reasonable price.

In this article, we will provide detailed information to answer all of the above questions, helping you better understand the product and make the most suitable choice for your project. Join us to discover the outstanding advantages of Cemboard panels and learn how to use them effectively in construction projects!

What is Cemboard cement board?

Cemboard panels, also known by many other names such as cement panels, 3D cement panels, Simbo or Simpo panels, and lightweight concrete panels, are a modern construction material produced from combined cellulose fibers. with other additives. This product stands out thanks to its outstanding features and application flexibility. Cemboard panels are commonly used in many different construction items, from ceilings, partitions to floor coverings. With good bearing capacity, waterproof and fire resistance, Cemboard provides effective and sustainable construction solutions, meeting the diverse needs of investors and architects in optimizing costs. and construction time while still ensuring project quality.

Cemboard panels are currently trusted by many people thanks to their outstanding advantages such as lightness, water resistance, good strength, and fire resistance. This is an effective alternative to traditional materials in construction. Some people wonder whether Cemboard panels can be bent or not. The answer is no, Cemboard cannot be bent, so you should not try to bend Cemboard when using it. Besides, Cemboard panels can also be painted to increase aesthetics and protect the surface. This product brings many benefits and meets a variety of construction needs, from ceilings, partitions to floor coverings.

Structural components of Cemboard panels

Cemboard panels are made from a mixture of cellulose fibers, Portland cement, ultra-fine silica sand and some other inorganic compounds. The production process begins by mixing these ingredients well, then pouring the mixture into standard sized molds. Next, the mixture is rolled and compressed under high pressure using hydraulic steam pressing. This method creates a strong connection between components, ensuring Cemboard panels have uniform thickness and high durability. Thanks to this advanced production process, Cemboard panels are not only light but also effective in bearing, water and fire, meeting strict requirements in construction.

After being compressed and pressed with hydraulic steam, the Cemboard panel continues to undergo the drying process in the oven with a stable temperature of about 1,300 degrees Celsius. This process helps make the product's structure more sturdy, while also Increases pressure resistance and bending resistance. Next, the Cemboard sheet is put into the cooling compartment to balance the humidity, ensuring product stability. Finally, the Cemboard panel is processed to flatten the surface, creating a finished product with high durability and good bearing capacity, meeting strict standards in the construction industry.

Cemboard cement panels currently have many diverse sizes on the market, with popular thicknesses including: 3.5mm, 4mm, 4.5mm, 6mm, 8mm, 9mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, and 24mm. These sizes meet many different requirements in construction projects, from ceilings, partitions, floors to other specific applications. The variety of thicknesses helps contractors and investors easily choose the product most suitable for the intended use and characteristics of each project.

SEE MORE PRODUCTS:

Cemboard cement panel production process

Cemboard cement panels are produced from main ingredients including wood fiber, cellulose fiber, Portland cement, fine sand and some other additives. The production process begins with mixing these ingredients in precise proportions, ensuring uniformity and high quality of the mixture. Then, the mixture is put into standard-sized molds, where it is pressed with enough force to create cement panels with solid bonds and high stability.

The use of advanced technology in the pressing process helps ensure that each Cemboard panel has good bearing capacity and a smooth flat surface. The components are perfectly combined, creating a product that not only has outstanding durability but is also effectively waterproof, fireproof and soundproof. Thanks to that, Cemboard cement panels become the ideal choice for many modern construction projects.

The stage of drying and firing Cemboard cement panels

After the Cemboard panels are pressed, they will go through a period of drying and firing at high temperatures. Initially, the panels are dried to remove moisture, then they are put into a furnace with temperatures up to 1300 degrees Celsius. This firing process not only helps the material become solid, but also significantly strengthens it. bearing capacity of Cemboard panels.

High temperatures cause the components in Cemboard panels to adhere more tightly, creating a final product with high durability and good load-bearing capacity. This process also contributes to enhancing the fireproof and waterproofing properties of Cemboard, making it the ideal material for many modern construction applications.

Thanks to the high temperature firing process, Cemboard panels not only meet strict quality standards but also have a long lifespan, resistance to harsh environmental factors, ensuring safety and durability. sustainable for projects using this type of material.

Cooling and processing phase of Cemboard cement panels

After the firing process, Cemboard cement panels are transferred to the cooling chamber to adjust humidity and prevent possible warping. Balancing moisture is an important step to help protect the structure of cement panels, preventing deformation due to sudden temperature changes.

Next, the Cemboard panels will go through a processing stage to create a flat, smooth and uniform surface. This process ensures that the final product meets high quality standards and provides the best user experience for consumers.

Through this period, Cemboard cement panels not only have high durability and stability but also have a smooth surface, making them easy to use and install in various construction applications. This makes Cemboard panels an ideal choice for many construction projects and interior and exterior decoration needs.

Quality inspection and packaging of Cemboard cement panels

Cemboard cement panels, after completing the production process, will undergo a strict quality inspection process, complying with European standards. Each panel must meet criteria for durability, load-bearing capacity and waterproofing before being packaged and shipped to consumers.

This advanced and strictly controlled production process is an important step to ensure that Cemboard cement panels always meet the high quality requirements of the construction industry. The product not only has outstanding durability but is also easy to construct, making it an ideal choice for many modern projects. This helps create a safe, sustainable and convenient living and working space for users.

Application of cemboard cement panels in construction

Cemboard cement panels are a popular and diverse material used in the construction industry. This type of material can easily be found in many different types of projects, performing many roles and functions not only in construction but also in decoration and finishing works. Below are some common applications of Cemboard cement panels:

Ceiling application

Cemboard panels with a thickness of 3.5 to 4.5 are commonly used for floating or recessed ceilings in construction projects. The strength of this product is its light weight, making it easy during construction. In particular, Cemboard panels with a thickness ranging from 3.5 to 4.5 mm have the ability to be cut and bent flexibly, allowing for easy and flexible application in positions such as curved corners or decorative motifs. than. This helps create unique and diverse ceiling structures, creating a highlight for the space and interior design of the building.

Application for wall partitions

Cemboard panels are designed with a flat, smooth surface to help increase the aesthetics and quality of construction projects. With this characteristic, Cemboard panels not only ensure uniformity and smoothness of the surface but also bring sturdiness and durability to the project. Cemboard panels are designed with many different sizes and weights, suitable for both indoor and outdoor use. This helps meet the diverse needs of construction projects, from ceilings, walls to exterior projects such as fences, retaining walls or partitions.

Floor lining application

Cemboard panels with thicknesses from 14mm, 16mm, 18mm, to 20mm are often used to construct attic floors and load-bearing raised floors in construction projects. With this thickness, Cemboard panels are resistant to force and durable, and can withstand large loads without causing deformation or damage. This makes them the ideal choice for areas requiring high durability and stability such as lofts and raised floors in construction and landscaping projects.

SEE MORE PRODUCTS:

Why should you use cemboard cement panels in construction?

Good fire resistance and heat insulation

Thanks to the non-flammable ingredients in the cement board, the product has good heat resistance and provides significant sound insulation performance. Therefore, this material is often chosen to construct projects that require sound insulation and fire resistance, such as soundproofing and fire prevention construction items.

High safety and compatibility

Cemboard cement board does not contain asbestos, is a green material that is safe for the health of users and the environment. With fiber cement structure, this product is compatible with many types of structures, including concrete and steel structures in construction. This allows cemboard panels to be installed and glued on concrete frames flexibly and effectively.

Durable, load-bearing floor covering

Cemboard cement panels, made from cement combined with wood chips, provide solid and durable properties. Thanks to this sturdy structure, the material has excellent impact resistance and heavy load capacity. This makes the product suitable for use as a floor covering in areas such as attics and boarding houses where high durability and strength are required.

Construction process is faster

Cemboard cement panels with a thickness of 14mm can be the perfect choice to create a solid floor, replacing the traditional heavy annealing process. For panels with a thickness of 6mm, they can be used as partitions to replace brick walls. The product's good bearing capacity and light weight help construction progress go faster. In addition, with a lifespan of up to 50 years, Cemboard cement panels are a long-term and stable choice for solid construction projects.

Cost savings

The price of cemboard panels usually depends on the thickness and size of the product. However, in general, the prices are suitable for consumers. Using this material to replace traditional materials can help investors save a significant amount of construction costs. This can mean reduced transportation, construction and maintenance costs, while also bringing high economic efficiency to the construction project.

SEE MORE PRODUCTS:

Address to buy reputable, quality cemboard panels

If you are looking for a reliable address to supply cemboard panels, Hoang Sa Viet Construction is a choice worth considering. This is a unit specializing in providing high-tech construction materials, including cemboard panels and AAC tiles, with a commitment to quality and reputation.

Hoang Sa Viet Construction's products are manufactured from quality materials, such as fly ash and coal slag, which not only ensure performance but are also environmentally friendly. The production process is carried out according to strict standards and is always inspected by leading experts in the industry.

With a commitment to quality and reasonable prices, Hoang Sa Viet Construction's products not only bring safety to health but also prolong the life of construction projects. Customers can be completely assured and trust the products of this unit.

Hiện chưa có đánh giá nào về sản phẩm này!

.jpg)

.jpg)

.jpg)