The system is processing. Please wait a moment!

Vui lòng lựa chọn loại báo giá!

- Home Product MATERIALS FOR PREFABRICATED HOUSES Prefabricated Wall Materials

Eps Panel Walls

TABLE OF CONTENTS

Increasingly severe climate change has led to an increase in global temperatures, making the need for insulation materials more popular than ever. Among them, EPS panels stand out thanks to their effective insulation and heat resistance and many outstanding advantages, becoming the favorite choice of many people. So what is an EPS panel? Let's join Hoang Sa Viet Construction to learn details about this material as well as receive a detailed EPS panel quote in the article below!

What is insulated EPS panel?

EPS insulation panels, also known as EPS plastic core insulation panels, are an outstanding heat-insulating and heat-resistant material for construction projects. EPS plastic core (abbreviation for Expanded Polystyrene) is a form of primary plastic. Through the process of processing and heat stimulation, EPS molecules create a plastic structure with high adhesion and firmness, helping to effectively enhance insulation and heat resistance. Thanks to these superior properties, insulated EPS panels become the top choice in protecting and improving energy efficiency for modern buildings.

What factors does the price of insulated EPS panels depend on?

The price list of insulated EPS panels can fluctuate, increase or decrease depending on many different factors. Some important factors that affect price include:

Raw material quality:

The price of insulated EPS panels is greatly influenced by the quality of input materials. Virgin EPS plastic, prized for its purity and thermal insulation performance, will cost more than recycled or low-quality plastics. EPS virgin plastic not only ensures sustainability and outstanding insulation ability but also increases the durability and longevity of the panel. On the contrary, using recycled plastic can help reduce production costs, but may affect the quality and insulation effectiveness of the product. Therefore, when choosing to buy insulated EPS panels , investing in high-quality materials will bring long-term benefits in terms of performance and durability of the project.

Thickness and size:

The price of insulated EPS panels also depends on the thickness and size of the product. Panels with greater thickness and larger sizes will usually cost more. This is because they use more raw materials during production and require more complex machining steps. Thicker panels not only increase thermal insulation but also improve the durability and load-bearing capacity of the building. Besides, the production of large-sized panels requires specialized processes and equipment, increasing production costs. Therefore, when choosing insulated EPS panels , users need to consider usage needs and costs to ensure optimal efficiency for their projects.

Production technology:

Modern and advanced production technology will create high-quality EPS panels with outstanding thermal insulation performance. Advanced manufacturing processes improve product durability, insulation and finish. However, applying these technologies also means increasing production costs, due to the need to invest in machinery, equipment and strict testing procedures. Therefore, the selling price of EPS panels produced with modern technology is often higher than those produced by traditional methods. Consumers need to consider this factor when choosing to ensure a reasonable investment and receive the best quality products for their projects.

Special technical requirements:

If EPS panels need to meet special technical requirements such as high bearing capacity, fire resistance, waterproofing or soundproofing, the price of the product will increase significantly. This is because the production of panels that meet high technical standards requires the use of special materials and advanced manufacturing technology. Fireproofing, waterproofing, and soundproofing materials are not only more expensive, but also require rigorous testing procedures to ensure safety and performance. Therefore, when there are special technical requirements, consumers need to be prepared for higher costs, but in return will receive products with optimal quality and efficiency, in accordance with standards. High technology of the project.

Order volume and quantity:

When ordering in large quantities, you will often enjoy attractive discount policies from the supplier. Purchasing in large volumes not only saves on shipping costs but also reduces product costs due to larger production scale and fixed costs being evenly distributed. On the contrary, if you order in small quantities, the price per EPS panel may be higher because you do not enjoy preferential prices from the supplier. This is because production and shipping costs are not optimized when producing and shipping small orders. Therefore, to save costs, you should consider ordering in bulk, especially when planning to use EPS panels for large or long-term construction projects.

Market and supply area:

The price of EPS panels also depends on the market and supply area. Areas with high market potential and abundant raw material sources often have relatively stable prices. However, in remote areas, where transportation and distribution are more difficult, prices may be higher due to higher transportation and distribution costs. This often occurs when supply is uneven or when the region has special transportation requirements, such as transportation across mountainous terrain or border areas. To ensure reasonable costs, understanding the market and supply area is very important when deciding to buy EPS panels.

Time and economic situation:

The price of EPS panels also reflects the time and economic situation. When demand increases or input materials are scarce, prices may increase. This often happens during periods of strong economic growth, when construction and infrastructure projects are being vigorously implemented. Conversely, during economic downturns or when supply exceeds demand, prices may decline due to downgrading of construction projects and increased competition among manufacturers. This is evident during difficult economic times or when the construction market is experiencing a slowdown. To understand the current price and economic situation, it is important to monitor the market and economic indicators.

Regularly updating EPS panel prices from a reputable supplier like Hoang Sa Viet Construction will help you grasp the most accurate and suitable price for your project. Hoang Sa Viet Construction's products not only ensure high quality but also have competitive prices, meeting the needs of many customers.

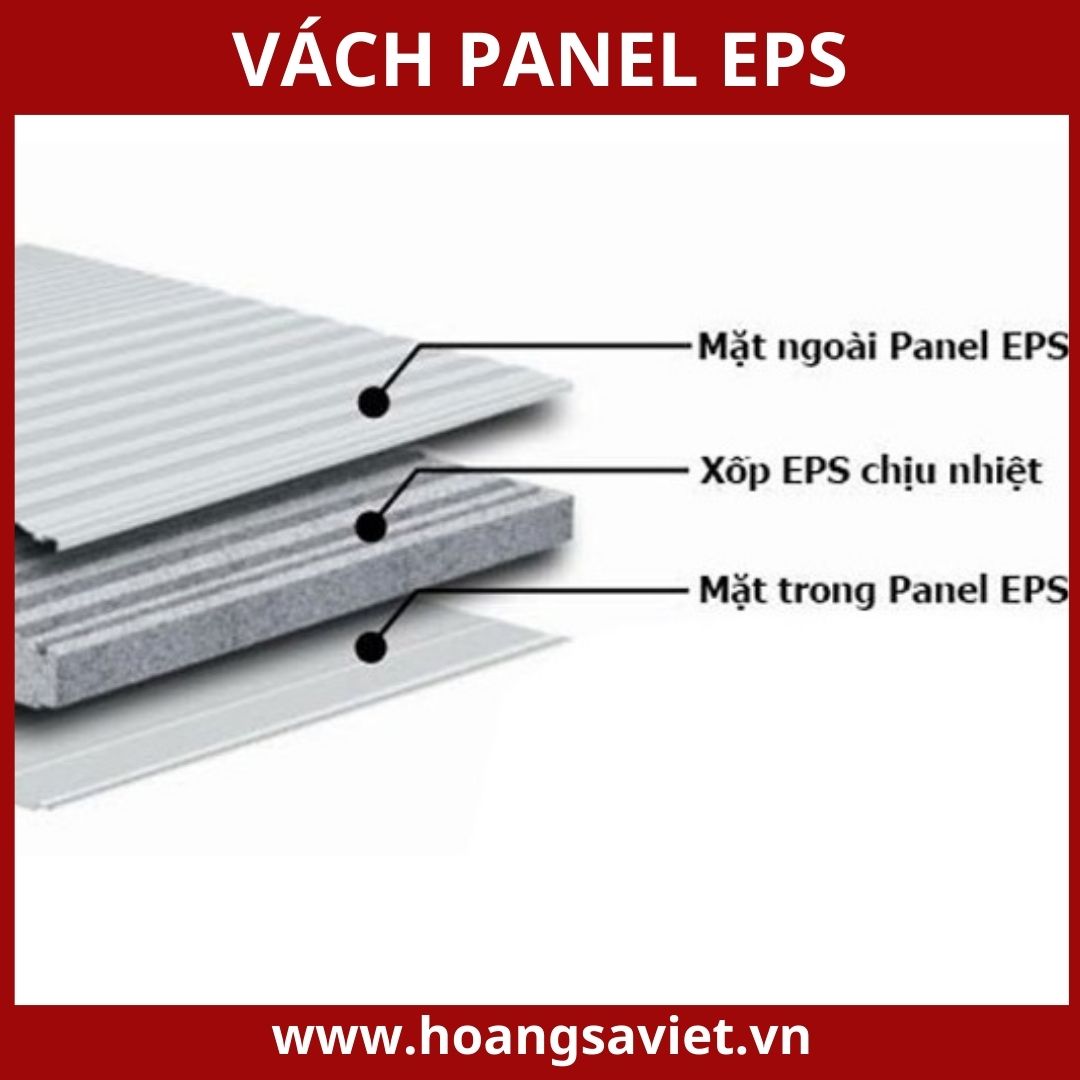

Structure of EPS insulation panel

The structure of EPS insulation panels is similar to conventional insulation panels, with two layers of corrugated iron on the outside and an EPS core on the inside. Two layers of corrugated iron protect the core and at the same time perform their contact functions, while the main core is the main thermal insulation. This creates a sturdy, pressure-resistant structure and provides stable thermal insulation for the panel.

The outer layer of corrugated iron

Commonly known as the top layer of corrugated iron, this material is usually zinc-aluminum alloy corrugated iron or PVC-coated corrugated iron. This layer of corrugated iron is often used for the outer surface of the panel, and often has a corrugated design to increase water drainage.

Due to direct contact with the outside environment, this corrugated iron layer is often treated with anti-oxidation to resist the effects of weather. For example, the use of PVC-coated corrugated iron helps the corrugated iron to be anti-rust, anti-corrosion, and resistant to extreme temperature conditions.

The thickness of the outer protective corrugated layer for EPS core panels usually ranges from 0.4mm to 0.6mm, creating a solid and reliable structure for the material.

EPS core layer

The EPS core, also known as foam or EPS plastic, is made from a series of plastic atoms, usually polystyrene. The conventional manufacturing process begins by dissolving plastic beads in a solvent, then pouring them into a mold to form the desired shape. Next, through the heat stimulation process at a temperature of about 90 degrees Celsius, the plastic is ejected from the mold, helping it change size and creating a honeycomb layer with a solid structure and tight connection.

In the EPS core, air bubbles are formed and tightly combined with the plastic, with the air component accounting for the majority, usually up to more than 90%. This combination creates an ultra-light structure while still ensuring durability and rigidity, while also providing excellent insulation and heat resistance for the EPS panel .

Inner surface corrugated layer

The inner corrugated layer, similar to the outer corrugated layer, is also treated with anti-oxidation to increase the durability and rust resistance of the insulated EPS panels . However, unlike the outer surface plating, which often has a stamped wave design, the inner plating is usually flat or lightly ribbed. This makes the EPS panel easier to apply and bond to other flat surfaces, creating a more uniform and smooth surface.

SEE MORE PRODUCTS:

Advantages of insulated EPS panels

Helps effectively insulate and prevent heat

With increasingly harsh climates, interest in insulation materials is increasing. Among them, EPS panels stand out for their effective thermal insulation ability, thanks to the closed foam core that does not create gaps, helping to effectively prevent heat. This product helps reduce heat transfer and has the ability to withstand heat from minus 60 degrees Celsius to 120 degrees Celsius, reducing the possibility of fire and maintaining it for a period of 15 - 20 minutes. In particular, EPS panels are popular in projects related to refrigeration, insulation and good heat retention.

Light-weight

One of the outstanding benefits of EPS insulation material is its lighter weight compared to conventional materials. This brings many conveniences during transportation, construction, maintenance and dismantling, helping these activities take place faster and easier.

Anti-noise and soundproofing ability

Besides heat insulation, EPS panel material is also widely used in making partitions with optimal sound insulation. This product can be effective in reducing noise in spaces such as homes, theaters, karaoke bars, recording studios, etc.

Thanks to the tight and uniform structure of the EPS core layer, EPS insulation panels can reduce sound transmission by up to 60%. This significantly reduces sound frequencies reaching neighboring spaces, creating a quieter and more comfortable environment.

Energy saving

During intensely hot days, equipment such as air conditioners, chillers, industrial fans, etc., not only for families but also for manufacturing businesses, must operate at maximum capacity to maintain Maintain desired temperature. To protect machinery and save energy, insulated fireproof EPS panels are often used. Compared to other types of insulation panels, panels with EPS core are especially suitable for refrigeration environments.

EPS partitions act as a protective layer, helping to insulate heat rays from the outside and keep cold temperatures inside. This effectively maintains the cold temperature inside, making machine operation more stable and gentle.

SEE MORE PRODUCTS:

Tips for choosing good quality EPS panels

EPS Panel is the most popular construction material today, especially in projects such as prefabricated houses, temporary houses, warehouses, workshops, and factories. Choosing the right EPS panel not only ensures quality but also keeps the quote reasonable and meets the strict requirements of the project. Here are some tips when choosing EPS panels:

About Weight : Priority is given to choosing insulated EPS panels with uniform, sturdy weight. Products produced on modern production lines often deliver outstanding quality and high durability.

About Surface : Choose heat-resistant EPS panels with a smooth, glossy surface. If there is a coating layer, choose panels with a regular and beautiful painted surface to increase the aesthetics of the project.

About Structure : Priority is given to choosing EPS panel partitions with a tight 3-layer structure, with a perfect glue layer, not peeling or separating. This ensures product stability and durability.

Regarding Accessories: Choose accessories with high oxidation resistance such as stainless steel. At the same time, you should choose accessories that suit your project and usage needs to avoid causing problems and wasting time returning them.

Hiện chưa có đánh giá nào về sản phẩm này!

.jpg)

.jpg)

.jpg)