The system is processing. Please wait a moment!

Vui lòng lựa chọn loại báo giá!

- Home Product prefab modular house

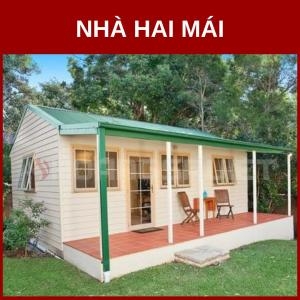

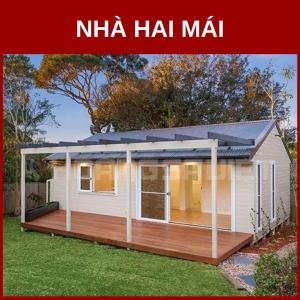

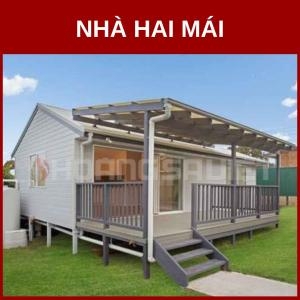

Cheap 2-Roof Prefabricated House

Code: NHM

-

Unit price: Calculated by m2 (From 3.5 - 5.5 million/m2)

-

Model: 2-roof prefabricated house (NHMLG)

-

Origin: Vietnam

-

Brand: Hoang Sa Viet Construction

-

Frame material: 2.5mm thick U160mm steel, tempered - electrostatic

-

Wall material: Specialized 50mm Panel with 3 layers of Glasswool

-

Insulation ability: 95%

-

Fire resistance: 100%

-

Connection Type: Smart Connector

-

Electrical system: Basic (LED lights, sockets, CB)

-

Warranty: 10 Years

TABLE OF CONTENTS

Two-roof houses have long been familiar to many people and are increasingly popular in Vietnam thanks to their simple design but still bring high aesthetics. Basically, a two-roof house is a type of house with a roof arranged separately in floors, which can be stepped or stacked, creating a unique visual effect. This type of roof is somewhat similar to a Thai roof but often has a simpler structure, suitable for many types of constructions.

Nowadays, with the continuous development of construction technology, double-roofed houses have many improvements in design and style. From classic to modern styles, this house model is increasingly diverse, meeting the needs of many customers and expressing personalization in each design. In particular, double-roofed houses are also integrated into the prefabricated house model, a quick and effective construction solution.

.jpg)

So, what is the difference between a prefabricated two-roof house and a traditional two-roof house? In fact, building a prefabricated house with two roofs not only saves time and costs but also provides flexibility in installation and disassembly. Furthermore, the materials used for prefabricated houses are often lightweight materials but still ensure durability and good resistance to weather conditions. The prefabricated two-roof house not only retains the beauty and function of the traditional two-roof house but also brings convenience, suitable for the needs of modern, fast, and flexible construction.

SEE MORE PRODUCTS:

WHAT IS A PREFABRICATED 2-ROOF HOUSE?

Double-roof prefabricated houses, also known as prefabricated houses, offer many differences compared to traditional houses. This type of house uses a main frame made of steel instead of conventional reinforced concrete materials, helping to reduce weight while still ensuring durability. The outstanding feature of double-roof prefabricated houses is that the roof is designed with two separate floors, creating a sophisticated and modern aesthetic feeling.

SEE MORE ARTICLES

20 Latest Container House Models This Year

Check out the 50 most beautiful smart prefabricated house models!

The process of building a two-roof prefab house is usually divided into three main stages. First is the design phase, in which architects will based on customer requirements to create detailed drawings of the size, shape and style of the house. The components are then machined at the factory, ensuring that all parts are manufactured according to technical standards, helping to shorten construction time on site. The final stage is the installation stage at the construction site, where the components are put together according to standard procedures, quickly creating a complete house.

Thanks to this advanced manufacturing and installation process, the double-roof prefabricated house not only saves time and costs but also offers flexibility, suitable for many different uses such as houses, resort villas, or offices.

STRUCTURE OF 2-ROOF PREFABRICATED HOUSE

A basic 2-roof house will include the following components:

1. Foundation structure of a 2-roof prefabricated house

The foundation is one of the most important factors in the construction of prefabricated houses, playing a role in supporting the entire house. Depending on the nature of the project as well as the requirements of the customer, the foundation will be constructed accordingly. With prefabricated houses, the foundation is often constructed more simply than with traditionally built houses due to the light weight of the house. This helps save costs and construction time. To ensure a solid foundation, the foundation is often built on a hard ground surface. In the case of weak or soft soil, it is necessary to add more rubble and compact it carefully to avoid subsidence.

Once the foundation surface has been prepared, the process of weaving D200 iron and pouring a layer of concrete 10-20cm thick will be performed to create a solid foundation for the prefab house. Thanks to this method, the construction of house foundations becomes faster and more effective, meeting the requirements of strength and durability.

SEE MORE PRODUCTS:

Double-roofed prefabricated houses are usually built with 2 to 3 floors, have flexible designs and are widely used for many different purposes. This is an ideal solution for building company offices, creating a modern and cost-saving working space. In addition, this type of house is also used as a house with an airy design, meeting the living needs of the family. Not only that, double-roofed prefabricated houses are also very popular in the tourism sector, especially homestays, providing a unique and comfortable resort space. Another application of this type of house is as a garden house, where the owner can enjoy a life close to nature but still comfortable.

3. Main frame structure of 2-roof prefabricated house

The prefabricated house frame is considered an important part, playing the main role of bearing the load and creating solidity for the entire structure of the house. This frame system is manufactured in the factory using precast method, helping to save construction time and ensure high accuracy in every detail. The house frame is usually processed from U-shaped or I-shaped steel bars with cross-sections from 160mm to 200mm, depending on the span and design of the house to ensure optimal load-bearing capacity.

SEE MORE ARTICLES

20 Latest Container House Models This Year

Check out the 50 most beautiful smart prefabricated house models!

One of the outstanding advantages of this frame system is the electrostatic painting process before being put into use. Powder coating not only helps protect the house frame from environmental impacts such as rust and corrosion but also prolongs the life of the house, ensuring sustainability over time. After the main frame is completed, other parts such as partitions, windows, and roof will be assembled directly onto the frame quickly and accurately, helping to shorten construction time while still ensuring quality.

Thanks to the convenience of the assembly process and good bearing capacity, prefabricated house frames not only provide high durability but also meet safety standards, giving owners complete peace of mind about their stability. of the house.

.jpg)

3. Secondary structure of the 2-roof prefabricated house

The secondary structure of a 2-roof prefab house plays an important role in completing the entire structure and creating sustainability for the house. Additional components include partitions, stairs, roof purlins and floors, all of which are meticulously designed and installed to ensure the sturdiness and stability of the project.

Partitions in 2-roof prefabricated houses are often made from lightweight materials but still ensure sound and heat insulation, making the living space comfortable and energy efficient. The stairs are designed to suit the space, creating convenience for moving between floors, and are also an important aesthetic element. The roof purlins, used to support the roof system, help distribute the load evenly and increase the stability of the entire building. Floors, with a solid structure, are often made from waterproof and durable materials, helping to improve sustainability and long-term usability.

SEE MORE ARTICLES

20 Latest Container House Models This Year

Check out the 50 most beautiful smart prefabricated house models!

Thanks to the unique two-roof design, the prefabricated house not only brings impressive aesthetic beauty but also helps optimize the drainage system and increase durability. This design not only increases the aesthetic value of the building but also contributes to the overall solidity, helping the house not only be structurally sustainable but also stand out in form.

4. Shaping part for 2-roof prefabricated house

To shape a 2-roof house, the most popular and effective material today is usually a high-quality galvanized corrugated iron roof. This material is not only highly durable but also helps the house withstand the effects of weather such as sun, rain, and strong winds. In addition to being resistant to corrosion and oxidation, galvanized roofing also brings a modern, sophisticated appearance, making the house more beautiful and impressive.

When designing and constructing a prefabricated house with 2 roofs , the structural system of the house will often be divided into two main parts. The first is the vertical covering structure, including elements such as walls, main doors, windows, and vertical skylights. These are the parts responsible for protecting the house from external impacts and creating a safe and comfortable living space for the homeowner.

SEE MORE PRODUCTS:

The second is the horizontal covering structure, including the roof and horizontal skylights. The roof not only has the function of covering and protecting the entire structure but also plays a role in effective drainage, ensuring that the house does not stagnate during the rainy season. Horizontal skylights help create ventilation, increase light and air circulation in the space inside the house.

The harmonious combination of vertical and horizontal structural systems helps the 2-roof prefabricated house achieve both aesthetics and sustainability, creating a living space that is both comfortable and impressive.

THE DIFFERENCE BETWEEN A PREFABRICATED 2-ROOF HOUSE AND A TRADITIONAL 2-ROOF HOUSE

| STT | Content | 2-roof prefabricated house | Traditional 2-roof house |

| 1 | Construction time |

Construction time is quick, depending on construction requirements, prefabricated houses with 2 roofs are usually completed in 2-3 days. |

It takes a long time to build, a house usually takes 1 month or more to complete. |

| 2 | Construction costs |

Construction time is shorter than traditional houses, helping to save labor costs. Use materials that are easy to find and cheap. |

Completion time is prolonged, resulting in additional costs for labor and construction materials. |

| 3 | Construction materials |

Using lightweight, highly durable, low-cost, flexible and removable materials such as: panel, cemboard, galvanized steel, stainless steel... |

Using heavy materials such as cement, bricks, stones, sand... are expensive and not flexible. |

| 4 | Convenience and quality |

Using lightweight materials makes it easy to transport and construct, and can be recycled. The foundation is not too complicated. Environmentally friendly, limits fine dust that affects health. Can be designed in many forms that are difficult for traditional houses to do. |

Use heavy, non-recyclable materials. The foundation requires high design and construction requirements. Environmental pollution, affecting health. |

BEAUTIFUL - MODERN - CHEAP 2-ROOF PREFABRICATED HOUSE MODELS

SEE MORE PRODUCTS:

CONTACT INFORMATION - HOANG SA VIET CONSTRUCTION

.jpg)

HOANG SA VIET CONSTRUCTION

Hiện chưa có đánh giá nào về sản phẩm này!

.jpg)

.jpg)