The system is processing. Please wait a moment!

Vui lòng lựa chọn loại báo giá!

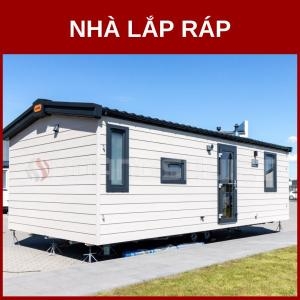

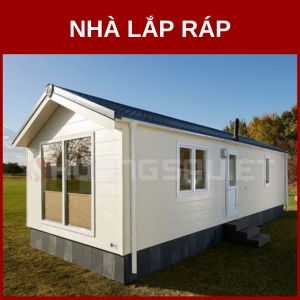

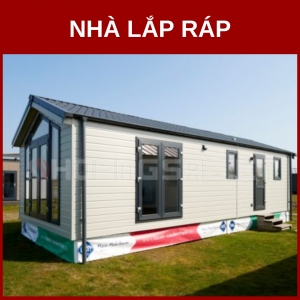

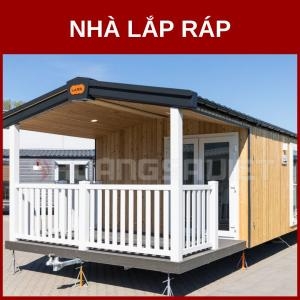

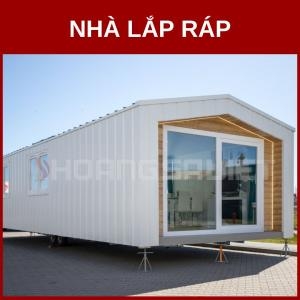

- Home Product prefab modular house

Assembly and Assembly House 6000USD / set

Code: NLR

-

Unit price: From 6000USD/set / unit for 32m2 - 1 bedroom

-

Model: Assembly house (NLR140)

-

Brand: Hoang Sa Viet Construction

-

Frame material: 2.5mm thick U160mm steel - tempered - electrostatic

-

Wall material: Dedicated 50mm panel with 3 layers of Glasswool

-

Heat insulation: 95%

-

Fire resistance: 100%

-

Connection type: Smart Connector

-

Electrical system: Basic (LED light, socket, CB)

-

Warranty: 10 Years

TABLE OF CONTENTS

The concept of an assembler is no longer strange to many people. This model is increasingly developing with a variety of design styles, applying more advanced technologies. Bringing an effective solution that addresses factors from time to construction cost. In the Vietnamese market, with many outstanding features, the assembled house model has received a lot of attention and is applied in construction in big and small provinces. Hoang Sa Viet Company is one of the construction and installation units nationwide . We also own a prefab factory with a scale of more than 5000m2, launching a series of prestigious and quality products. Today, let's learn about "Assembly Products" of Hoang Sa Viet!

WHAT IS AN ASSEMBLY?

The assembler has many other names such as the assembler, the prefab house, the prefab house or the panel house. These houses have a different structure than traditional houses, built from materials such as steel, panel, cemboard… But the assembled house still has most of the elements of a traditional house: solidity. sure, safe, sustainable, high aesthetic. There are also more outstanding features such as ease of movement, ease of assembly, quick construction and importantly, optimization of construction costs. So what is the structure of a prefab house?

The assembler has 2 basic sizes:

+ Assembly house 18m2: 6m long x 3m wide x 3m high.

+ Assembly house 24m2: 6m long x 4m wide x 3m high.

+ 32m2 assembled house: 4m long x 4m wide x 3m high. Design 1 living room + bedroom + kitchen = From 6000USD/set

CONSTRUCTION AND MATERIALS OF THE MANUFACTURER

1. Structure of prefab house

If you are in the process of learning the information about a prefab house, this will be a much-needed piece of information. Basically, an assembled house will be composed of components:

+ The assembled house frame: this is a very important component, the steel valley system is fixed to connect the partitions and joints to form a complete house..

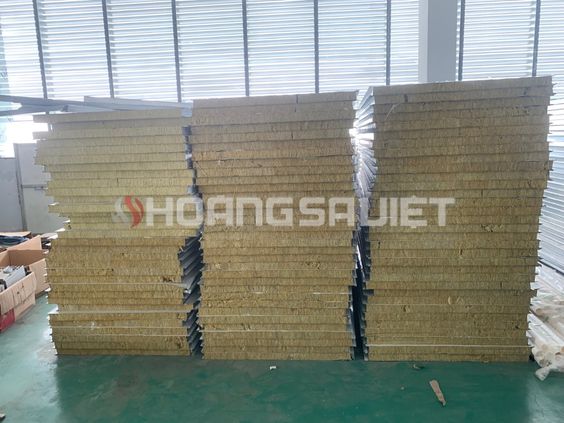

+ Partitions, walls: the wall will be used with 3-layer glass wool panels to replace the usual construction method of brick and cement.

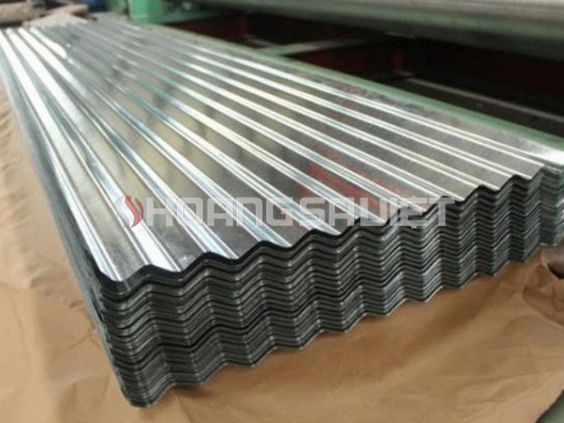

+ Roof: using galvanized sheet, powder coated and covered with a panel wall.

+ Door system: depending on individual requirements, 1 or more doors will be designed.

+ Bracing system (storm protection system): is an essential part of the house that has the effect of keeping the house firmly against all inclement weather.

+ Gutter system: is installed on the roof, has a drainage pipe to keep the house from stagnant water.

2. What materials will be used when building the prefab house?

| TABLE OF MATERIALS USED FOR CONSTRUCTION | ||

| Material name | Detail | Image |

| Steel | The steel used is of high quality, stainless. Steel is used to make frames, foundations, trusses, columns, purlins. |

|

| Panels | There is a layer of high-grade glass wool, heat insulation, soundproofing, fireproofing. Use as partitions or can be used as the main door. The price of this product is very reasonable and easy to use. |

|

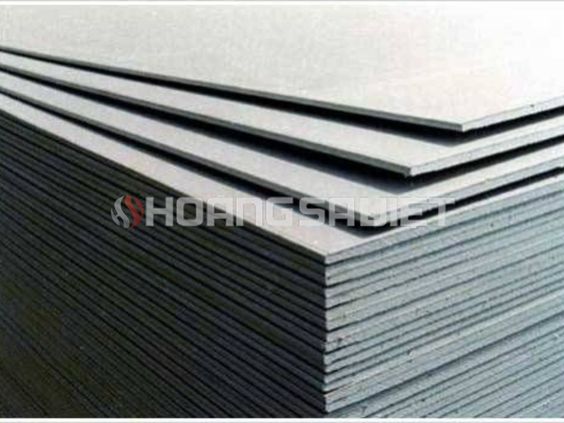

| Cemboard plate | Can be called a lightweight concrete slab, made of cement, sand, and cellulose fibers. Used to line the floor with many advantages such as fireproof, anti-slip, good bearing. |

|

| Galvanised aluminium | The roof is made of galvanized corrugated iron, anti-rust, anti-oxidation, long life, low cost |

|

DIFFERENCE BETWEEN ASSEMBLY AND TRADITIONAL HOUSE

What is the difference between prefab house and traditional house? Let's find out with Hoang Sa Viet!

+ First, the most obvious difference is in construction materials. Assembled houses do not use as much cement, stone, and sand as traditional houses, only to fix the foundation. The foundation of the prefab house will be made simpler.

+ Faster construction speed. The process of completing an assembled house takes only half the time of a traditional house. Because the assembly components are already manufactured in the factory, just bring them to the installation site and assemble them together.

+ Can be easily moved. Being linked together by partitions and flexible joints, moving the prefab house to another location is very easy.

+ Environmentally friendly. There are no construction processes like traditional houses, helping to reduce fine dust that affects health. Recyclable and reusable.

PROCESS OF BUILDING ASSEMBLY IN HOANG SA VIET

At Hoang Sa Viet, we have plans and processes in place to complete the most standard and tight assembled houses. A process of completing a prefab house includes the following stages:

Stage 1: Sketching the design idea

Before proceeding with construction, each client has his own ideas for his house. From modern, rustic, simple or sophisticated styles, there will be a staff to advise and navigate the ideas of customers most thoughtfully.

Stage 2: Exploiting ideas, forming detailed drawings

Architects of Hoang Sa Viet will work with customers to exploit ideas to create detailed drawings. We will support customers to complete basic drawings at no cost and design more detailed 3D drawings if required.

Stage 3: List the materials used and the budget to complete the house

The list of materials used for construction is detailed in the quotation for customers to easily follow.

Stage 4: Construction contract

We will have a clear construction contract with specific terms so that customers can understand in detail their rights.

Stage 5: Carrying out the construction according to the plan

After completing the above stages, Hoang Sa Viet's technical staff will begin to participate in transporting materials to the installation site and building the assembly house.

Stage 6: Finishing the interior

Install the furniture according to the existing drawings, if there are additional installation requirements during the construction process, the technical staff will support the customers.

Stage 7: Handover and acceptance

After completing the construction, ensure the quality of the work, in accordance with the requirements of the investor. We will hand over and let customers check and accept the project.

CHEAP INTELLIGENT ASSEMBLY MODELS FROM 140 MILLION ONLY

CONTACT INFORMATION - HOANG SA VIET CONSTRUCTION

.jpg)

Hoang Sa VIETNAM CONSTRUCTION

See more products of Hoang Sa Viet in Vietnam :

Hiện chưa có đánh giá nào về sản phẩm này!