The system is processing. Please wait a moment!

Vui lòng lựa chọn loại báo giá!

- Home Product BUNGALOW HOMESTAY HOUSE

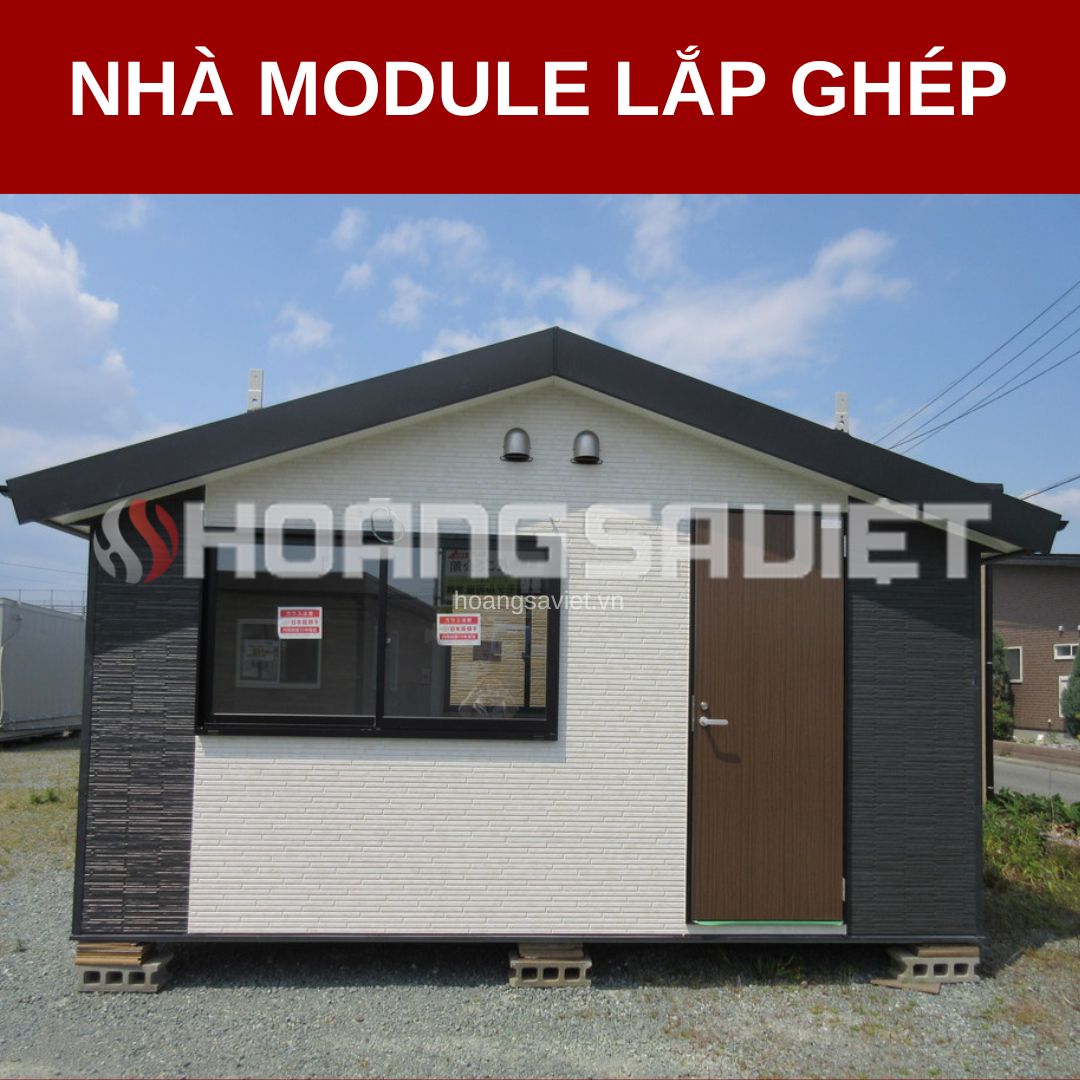

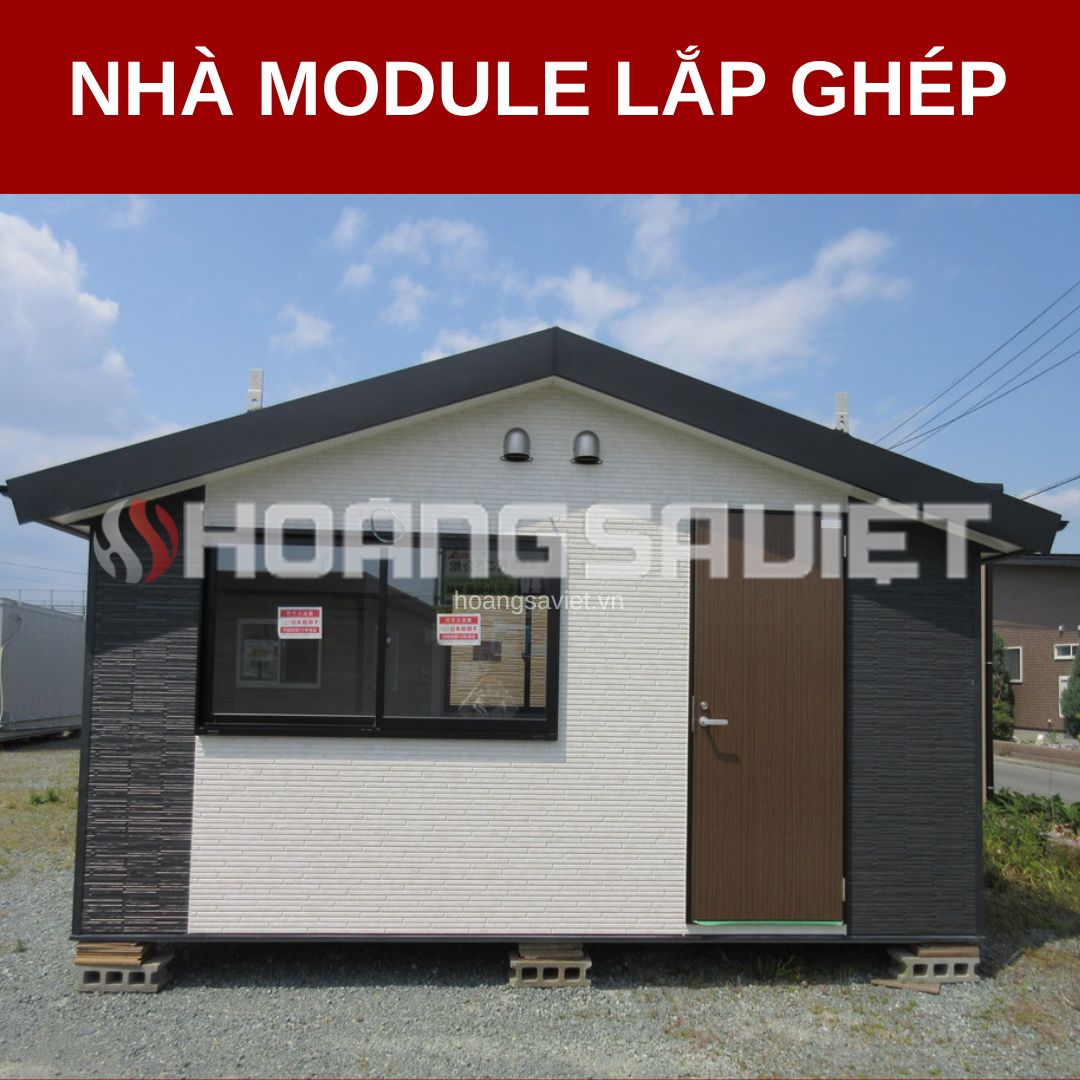

Module House Assembled

Code: MDLG

- Unit price: 1 piece (or according to m 2 if interior adjustment)

- Model: MDLG

- Made in Viet Nam

- Brand: Hoang Sa Viet Construction

- Frame material: 2.5mm thick U160mm steel - tempered - electrostatic

- Wall material: 50mm dedicated 2-layer Rockwool Panel

- Heat insulation: 95%

- Fire resistance: 100%

- Connection type: Smart Connector

- Electrical system: Basic (LED light, socket, CB)

- Warranty: 10 Years

Model of prefab house according to modern technology is creating a new wave in the field of construction architecture. The application of new materials and modern prefab construction technology has brought customers admirable construction works. To understand more about the outstanding features, uses as well as affirm the quality of the prefab house, let's explore the production technology and modularization of this interesting architectural model.

Modular houses , also known as prefabricated houses , are manufactured and pre-assembled at the factory and then moved to the desired location. Currently, modular houses or prefab houses are compared to smart houses for modern people today and are gradually being widely used because of their outstanding advantages and eye-catching designs.

What is a modular house?

Modular house is a house manufactured in a factory based on assembling components that have been modularized according to a certain standard. After completing the installation, the house will be transported by container to the site.

The main materials to form the assembled modular house are panel walls and frames, beam frames, the house is designed to bear loads based on iron and steel frames to ensure absolute safety for users. The time to install a house depends on the level of requirements of the owner but is usually very quick.

From the interior - exterior are exchanged, measured, carefully calculated to complete the house in the most accurate way. Once completed, the module house will be brought to the location where the house is to be installed.

SEE MORE ARTICLES:

Cheap Container Office Models For Sale And Rent!

Model of Prefabricated House From 50 Million In Hoang Sa Viet

Building a modular house

The pre-assembled module house has a high-quality steel frame structure, creating certainty and has systems like the model of a modular house: System of columns, System of visors and partitions, System of corrugated iron roof, System of braces Windproof to ensure user safety, Doors and windows, Gutter system, Electrical system and ventilation system.

When customers have a need to install fixed interior parts such as beds, cabinets, household appliances, etc., the technical team will support the design and construction according to the customer's requirements.

The rest, ie the raw house, customers can equip and decorate the items and furniture according to their own preferences after the complete house is handed over to the customer.

Advantages of modular houses in construction

Modular prefab houses with many outstanding advantages such as cheaper prices than traditional houses in the same segment, the same size, quick installation time and easy transportation to anywhere you want. Prefab houses are not limited by terrain, in addition, you can also expand the size or raise more floors if needed.

1. Save time: the time to complete the house only takes about a few weeks (depending on the size and style of the house). In addition, products delivered to customers are not affected by weather conditions because everything is already manufactured in the factory, just need to be brought to the construction site and installed.

2. Design flexibility: modular house can be changed in different sizes and designs, it is not bound by any framework, in addition, because this is a pre-assembled house, it can be easily easy to move anywhere.

3. Cost savings: With a short construction period, the modular house saves about 30% of the cost compared to a conventional concrete house because the materials are already manufactured, so the problem of development costs is limited. birth and labor costs.

4. Environmental protection: The prefab modular house was born to solve the dust problem by environmentally friendly, recyclable materials. Some surveys by scientists show that exposure to fine dust for a long time will affect the respiratory and cardiovascular systems, especially children, pregnant women, the elderly, especially the elderly. birth defects in young children.

Modular house construction process

Techniques for building modular houses

Modular house construction involves manufacturing individual building components off-site in a temperature-controlled factory and delivered for on-site installation. These prefab components can be considered "flat", like wall panels and roof trusses, and do not themselves cover the space. Also known as “panel” or 2-dimensional (2D) to describe their cross-sectional assembly, the process of installing panel prefab components consists of first placing them on the floor, then carefully lowering them. each wall section and fix them in time position.

Modular construction: A form of prefab construction, also known as a 3-dimensional (3D) or volumetric structure, the term module is key to understanding what a modular structure is. Unlike “prefabricated” components in general, with a modular home structure, the entire module is prefabricated outside and delivered for installation on site, like Lego blocks put together one by one. Piece. Modules refer to a specific type of built-in component such as complete rooms, corridors or space enclosing sections.

Modular house construction process

A pre-assembled modular house has a simpler construction process than a traditional house, but to complete a complete product, a prefab modular house must also have a completely scientific, elaborate and meticulous construction process. Here are the six basic steps that are essential in every modular construction project:

Step 1: Construction of the foundation for the project

Determine the centerline and height to place the fixing bolts down as shown in the module drawing. Then weld the bolts into clusters to form a solid foundation for the house. Check the hardness and fix it, difficult to rotate, finally pour concrete to create a complete pillar foundation.

Step 2: Install the main frame

The main installation part of the modular house: Installing the first column and truss is the most important, helping to shape the whole project. Depending on the location, geology and construction ground, people can install columns and trusses first from the middle of the house and then deploy to the two sides of the gable, or from the gable of the house.

The house frame is one of the most important parts in the construction process of the modular house. The installation of the main frame helps the worker to initially form the house that needs to be installed and has an appropriate construction method.

Step 3: Roofing corrugated iron

Like the main frame installation, the roof corrugated iron installation also requires the first sheet to be done very carefully, it is the focal point for the later installed corrugated iron panels.

It is necessary to take marks for each sheet of corrugated iron, making sure that after the construction is completed, all the overlapping points of the corrugated iron sheet are always on a straight line and perpendicular to the purlin bar.

A special note is that for buildings with additional insulation cotton under the roof, this must be implemented to ensure that the joints of the insulation cotton are straight, without shrinkage, the underside of Insulation cotton is flat, not wrinkled.

Step 4: Assemble parts at the construction site

The construction and installation stage of corrugated iron for construction is similar to the installation of roof corrugated iron. The construction of corrugated iron is not as complicated as the construction of corrugated iron because the corrugated iron aperture is not too long.

The remarkable point when constructing corrugated iron wall is to combine with the Builder from the very beginning to ensure the matching of the work between the installer of the module house and the construction.

Step 5: Finalize the product and test it

This is the final stage of the construction and erection of pre-engineered steel buildings, requiring meticulousness and precision in each stage. At this stage, it is imperative to re-check the bolts, the gaps at the joints, the crevices in the ventilation openings to ensure that there are no leaks later and the quality of the work is constructed. The door installation stage is constructed in this phase.

Modular prefab house is forecasted to become extremely popular in the coming years due to its convenience and savings.

Step 6: Hand over the product, instructions for use, maintenance and warranty repair service from Hoang Sa Viet Construction

The final step of this process is handing over the finished product to the customer. At that time, the technical team will guide customers to know how to use the house for the longest time. In addition, Hoang Sa Viet Construction will provide repair and warranty documents for customers to use and contact when they need support.

Models of assembled modular houses

Here are some modern and cheap modular houses for your reference:

Address to build a prestigious modular house

HSV Construction - Building Trust - Building Golden Prestige

If you want modular prefab houses with modern, sophisticated design, full amenities, flexibility in environments and adaptation to different weather conditions, reasonable prices, easy assembly and disassembly. For ease and flexibility in moving, please contact Hoang Sa Viet - Building Trust - Building Golden Prestige.

For a more detailed quote and consultation, please contact:

0907.090.551 - Ms. Linh - Linhngoc@hoangsaviet.com

0943.171.191 - Mr. Loi

Hoang Sa VIETNAM CONSTRUCTION

Hiện chưa có đánh giá nào về sản phẩm này!