The system is processing. Please wait a moment!

Vui lòng lựa chọn loại báo giá!

- Home Product prefab modular house

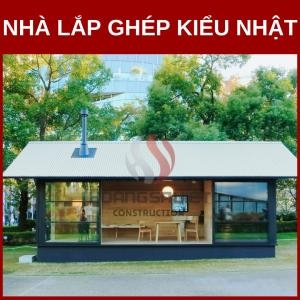

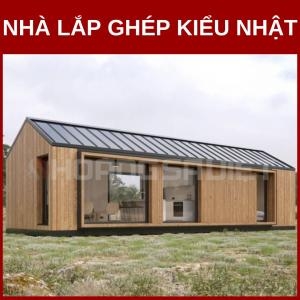

Japanese Style Prefab House

Code: Nhà Lắp Ghép Nhật Bản

-

Unit price: Per m2

-

Model: Japanese Style Prefabricated House (NLGKN)

-

Origin: Vietnam

-

Brand: Hoang Sa Viet Construction

-

Frame material: 2.5mm thick U160mm steel, tempered - electrostatic

-

Wall material: 2-layer Glasswool 50mm specialized panel

-

Insulation capacity: 95%

-

Fire resistance: 100%

-

Connection Type: Smart Connector

-

Electrical system: Basic (LED lights, sockets, circuit breakers)

-

Warranty: 20 Years

TABLE OF CONTENTS

In Japan, which is often faced with earthquakes and natural disasters, the prefabricated house model has become a popular and preferred choice. This type of prefabricated house not only brings many benefits such as low construction costs and the ability to disassemble and move easily, but also helps to minimize the impacts of natural disasters. Prefabricated houses in Japan often have a unique beauty, clearly reflecting the cultural identity of the land of the rising sun. So, what are the characteristics of a Japanese-style prefabricated house? Let's explore the characteristics and benefits of this type of prefabricated house, to better understand why it is so popular in this country.

See more products of Hoang Sa Viet in Vietnam :

WHAT IS A JAPANESE-STYLE PREFABRICATED HOUSE?

Japanese-style prefabricated houses , also known as Japanese prefabricated houses, stand out with their minimalist, sophisticated and modern designs, reflecting the typical style of the land of the rising sun. This type of house is made from new technological materials, completely different from traditional materials such as cement, bricks and stones. The construction process begins at the factory, where joints, components and partitions are pre-assembled. These parts are then transported to the construction site and completed on-site. Japanese-style prefabricated houses are built in the form of modules with a solid and sturdy structure, capable of effectively resisting earthquakes. In addition, this model also possesses many other outstanding features, increasing the comfort and sustainability of the living space.

FEATURES OF JAPANESE PREFABRICATED HOUSES

1. Japanese style prefabricated house Using Japanese standard quality materials

Japanese-style prefabricated houses are distinguished by the use of high-quality building materials that meet Japanese standards, ensuring superior performance and durability. These materials are manufactured under strict quality control in modern factories, where the most advanced technology is applied to ensure that each product meets optimal standards.

The building materials of Japanese-style prefabricated houses often include components with superior sound and heat insulation capabilities, helping to create a comfortable and energy-saving living environment. In particular, these materials also have good fire resistance properties, ensuring the safety of residents in all situations.

A special feature of Japanese-style prefabricated houses is that the products are designed and manufactured according to original Japanese standards. This not only ensures consistent and stable quality but also helps optimize the performance and durability of the components in the house. All these factors work together to create prefabricated houses that not only fully meet functional and safety requirements but also provide a modern and sophisticated living space.

SEE MORE PRODUCTS:

2. Japanese style houses reduce construction time

Japanese-style prefabricated houses stand out for their ability to shorten construction time thanks to their advanced and efficient construction process. One of the main factors that helps reduce construction time is that most of the construction stages are carried out in the factory. This process helps to minimize the impact of weather, a common problem in conventional construction projects.

Thanks to modern manufacturing technology and careful preparation of each joint and component, Japanese-style prefabricated houses can be assembled on site in just 7 to 10 days. This speed not only saves the homeowner waiting time but also reduces overall construction costs.

In Japan, Japanese-style prefabricated houses have become the main construction method, widely used in up to 90% of the country. This not only reflects the popularity of this type of house but also proves the efficiency and reliability it brings. The fast and efficient construction process of Japanese-style prefabricated houses helps homeowners quickly have the living space they want, while minimizing inconvenience and delays during the construction process.

3. Japanese-style prefabricated houses reduce construction costs

Japanese-style prefabricated houses not only stand out for their quick construction time but also for their significantly lower construction costs compared to traditional construction methods. One of the main reasons why prefabricated houses tend to reduce costs is the reduction of material waste. While traditional house construction often encounters excess materials, prefabricated houses are designed and manufactured based on precise drawings, which helps optimize the use of materials and minimize waste.

Ngoài ra, quy trình thi công nhà truyền thống thường yêu cầu nhiều nhóm thợ phụ chuyên biệt, chẳng hạn như thợ ống nước, thợ điện, và các chuyên gia khác, tất cả đều cần làm việc trong khoảng thời gian dài, dẫn đến chi phí nhân công cao. Trong khi đó, xây dựng nhà lắp ghép chỉ cần từ 2 đến 3 công nhân là có thể hoàn thành nhanh chóng, giúp giảm đáng kể chi phí nhân công.

Tại Hoàng Sa Việt, chi phí xây dựng mỗi mét vuông của nhà lắp ghép kiểu Nhật chỉ dao động từ 5-7 triệu đồng, một mức giá cạnh tranh đáng kể. Việc giảm chi phí không chỉ đến từ việc tiết kiệm nguyên vật liệu và chi phí nhân công, mà còn nhờ vào sự tối ưu hóa trong quy trình sản xuất và lắp ráp. Điều này mang lại một giải pháp xây dựng hiệu quả về mặt kinh tế cho các chủ đầu tư và khách hàng.

XEM THÊM SẢN PHẨM:

4. Nhà lắp ghép kiểu nhật có tính linh hoạt cao

Nhà lắp ghép kiểu Nhật nổi bật với tính linh hoạt cao, là lựa chọn lý tưởng cho nhiều nhu cầu xây dựng khác nhau. Một trong những ưu điểm đáng chú ý của loại nhà này là khả năng tháo lắp và di chuyển dễ dàng. Điều này không chỉ giúp tiết kiệm chi phí trong việc thay đổi địa điểm mà còn cho phép các chủ sở hữu linh hoạt hơn trong việc chuyển đổi không gian sống của mình.

Bên cạnh đó, nhà lắp ghép kiểu Nhật có khả năng xây dựng trên nhiều loại địa hình khác nhau, từ đồi núi, ven biển đến thung lũng và các khu vực có diện tích nhỏ. Loại nhà này được thiết kế để chịu đựng các điều kiện thời tiết khắc nghiệt, đảm bảo độ bền và sự ổn định trong mọi hoàn cảnh.

Một lợi thế lớn khác của nhà lắp ghép kiểu Nhật là khả năng mở rộng diện tích dễ dàng. Khi có nhu cầu, bạn có thể mở rộng không gian sống mà không gặp phải các khó khăn phức tạp như trong xây dựng truyền thống. Ngoài ra, nếu không còn nhu cầu sử dụng, nhà lắp ghép có thể được tháo rời và di chuyển đến vị trí mới hoặc thanh lý dễ dàng mà không phải chịu lỗ lớn như khi bán một ngôi nhà xây dựng truyền thống. Điều này mang lại sự linh hoạt và tiết kiệm cho các chủ sở hữu, đồng thời làm cho nhà lắp ghép kiểu Nhật trở thành một giải pháp xây dựng tối ưu và hiệu quả.

5. Nhà lắp ghép kiểu nhật thân thiện với môi trường

Nhà lắp ghép kiểu Nhật được thiết kế và xây dựng theo những nguyên tắc thân thiện với môi trường, điều này phản ánh sự quan tâm sâu sắc của Nhật Bản đối với bảo vệ tài nguyên thiên nhiên và giảm thiểu tác động tiêu cực đến môi trường. Nhật Bản, với nguồn tài nguyên thiên nhiên hạn chế, đã hình thành một thói quen sử dụng các vật liệu xây dựng không gây hại cho môi trường.

When building a Japanese-style prefabricated house , the process is strictly controlled by strict standards and regulations of the Japanese government. This includes ensuring that the materials used do not affect the surrounding environment, while limiting the exploitation of natural resources such as sand, stone, and soil.

The method of building prefabricated houses also contributes to reducing environmental pollution during the construction process. Compared to traditional construction methods, prefabricated houses have the advantage of reducing noise, fine dust and waste released into the environment. This not only creates a cleaner and more comfortable living space for residents but also protects the health of the community and the surrounding environment. From the choice of materials to the construction process, Japanese-style prefabricated houses always aim for sustainability and environmental protection, bringing long-term benefits to both users and the planet.

SEE MORE PRODUCTS:

6. Japanese style houses have very good sound and heat insulation.

Japanese-style prefabricated houses feature superior sound and heat insulation, meeting the high demands for comfort and energy efficiency in the living environment. Designed with special attention to temperature and sound control, these houses use high-quality materials to achieve optimal sound and heat insulation performance.

The structure of the Japanese-style prefabricated house includes an effective insulation treatment system, with the panels and the exterior wall panels made from advanced materials. Between these two panels, there is a layer of specialized glass called Glasswool. This material layer plays an important role in improving the soundproofing and insulation of the building, helping to minimize the phenomenon of vaporization and prevent heat transfer from the outside environment.

Thanks to the high-quality design and materials, Japanese-style prefabricated houses have up to 90% soundproofing, providing users with quiet and comfort. Compared to prefabricated houses manufactured in Vietnam, Japanese-style prefabricated houses are not only equivalent to, but also have better soundproofing, even surpassing, traditional brick-walled houses here. This ensures that when living in a Japanese-style prefabricated house, you will enjoy a quiet and temperature-stable living environment, providing comfort and a higher quality of life.

6. Japanese-style prefabricated houses have a durability of up to 30-50 years depending on weather conditions.

Japanese prefabricated houses are known for their exceptional durability, with a lifespan that can last from 30 to 50 years, depending on the weather conditions where the house is built. Japanese prefabricated houses are most durable in dry and cool climates where there are few fluctuations in temperature and humidity. In these conditions, the house can last up to 50 years, ensuring stability and durability over a long period of use.

However, in areas with hot and humid tropical climates or large temperature changes, the lifespan of Japanese prefabricated houses is usually between 30 and 40 years. Although slightly less than ideal, the durability of these houses is still impressive and fully meets the needs of long-term use. This proves that Japanese prefabricated houses are a durable investment, suitable for many different climatic conditions, and at the same time provide a sustainable and efficient construction solution for modern construction projects.

JAPANESE-STYLE PREFABRICATED HOUSE CONSTRUCTION PROCESS

To complete a Japanese-style prefabricated house , the following stages are required:

Phase 1: Fixing the foundation and house

To ensure the stability of the house, the soil properties must be checked to plan the foundation. Areas with weak ground and prone to subsidence need to have fixed stakes placed to secure the house.

Phase 2: Steel frame installation

According to the technical drawings to start building the house frame. The steel house frame used must be safe and durable, along with standard quality. Technicians assemble, shape the house frame and use screws and bolts to create solidity for the house.

Phase 3: Building walls, partitions, and roofs

After completing phase 2, assemble the walls and floors according to the drawings. The carefully constructed joints help the house withstand harsh weather conditions.

SEE MORE PRODUCTS:

Phase 4: Install windows and doors

The door frame connected to the wall must ensure accuracy, ensuring the door can be pulled in and out easily. In this step, it will be done by highly skilled and experienced workers.

Phase 5: Install interior equipment, wooden flooring, decorative wall panels according to 3D design.

Phase 6: Decorate the landscape to make the house closer to nature, creating unique features for each family. Each style will be presented differently through the combination of the house and landscape decoration, welcome gate, walkway...

Phase 6: Complete final steps and accept the project

After completing the house finishing and general cleaning stages, the house will be handed over and accepted.

BEAUTIFUL JAPANESE-STYLE PREFABRICATED HOUSE MODELS

BEAUTIFUL PREFABRICATED CONTAINER HOUSE MODELS

SEE MORE PRODUCTS:

CONTACT INFORMATION - HOANG SA VIET CONSTRUCTION

.jpg)

See more products of Hoang Sa Viet in Vietnam :

HOANG SA VIET CONSTRUCTION

content

.jpg)

.jpg)

content